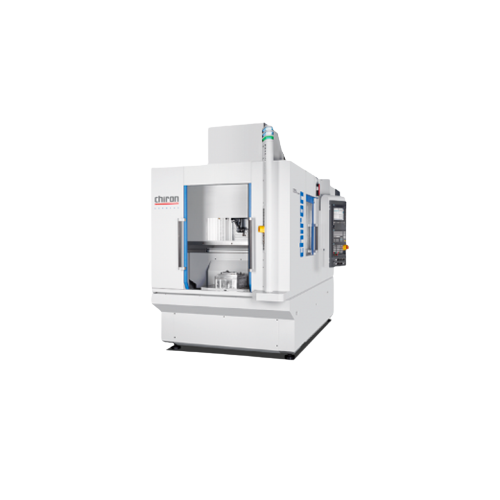

A machining center of the CHIRON 15 Series

CHIRON

PRODUCTIVE, FAST AND COMPACT

- -Reliably high productivity

- -Highest precision and processing quality

- -Reduced space requirements

- -Fast set-up

- -Simple operation

- -High stability

- -High dynamics

- -Easy maintenance

A machining center of the CHIRON 15 Series is one of the best machine tools of its class in terms of speed, compact construction, stability and reliability.

The machine tools of the 15 series have huge reserves for powerful CNC milling. Numerous configuration and equipment options enable the ideal solution for any job. All models are available with one spindle, with two spindles or four spindles. In addition, there is an MP version for processing profiles

HIGH PRECISION AND POWERFUL CUTTING

Due to its modular design, each machining center of the 15 Series can be assembled to form a perfect individual solution. Thus, you can choose between a lightning-fast basket tool changer or a pick-up tool magazine, for example. Furthermore, different spindle and table versions are available.

Your benefits: High precision and powerful cutting as well as maximum availability at lower unit costs.