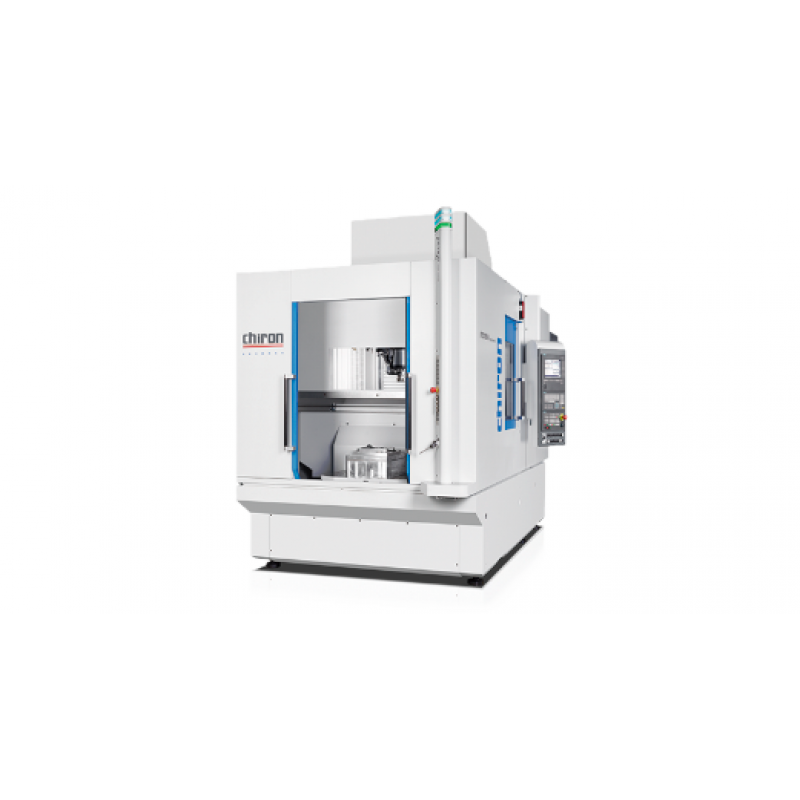

A machining center of the CHIRON 18 Series

CHIRON

COMPACT, STRONG AND FAST

FOR PRODUCTIVE CUTTING

Reliably high productivity

Powerful drives

Highest precision and processing quality

Fast set-up

High stability

High dynamics

Simple operation

Easy maintenance

A machining center of the CHIRON 18 Series is one of the best machine tools of its class in terms of its cutting performance, high working speed, precision and reliability.

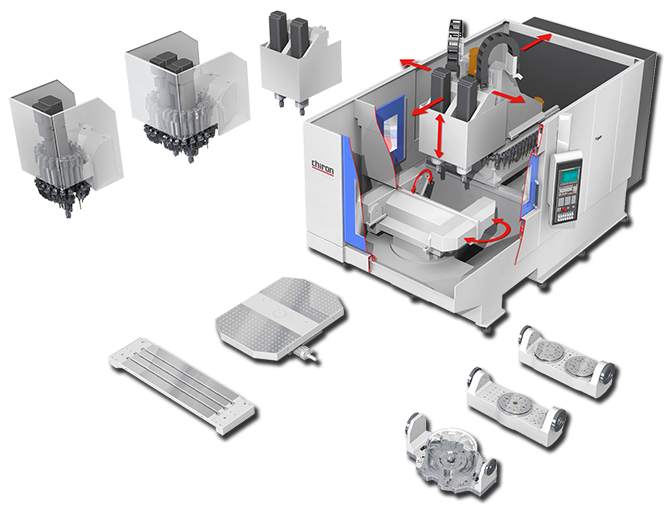

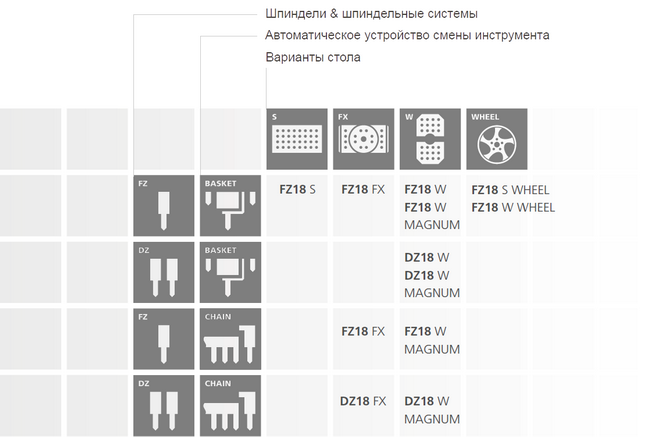

Numerous configuration and equipment options enable the ideal solution for any job. All models of the 18 Series are available with one spindle, with two spindles or four spindles.

POWERFUL MILLING AT LOW UNIT COSTS

EACH CNC MACHINE HAS ENORMOUS PERFORMANCE RESERVES FOR POWERFUL MILLING. DUE TO ITS MODULAR DESIGN, EACH MACHINING CENTER OF THE 18 SERIES CAN BE ASSEMBLED TO FORM A PERFECT INDIVIDUAL SOLUTION. THUS, YOU CAN CHOOSE BETWEEN A LIGHTNING-FAST BASKET TOOL CHANGER OR A PICK-UP TOOL MAGAZINE, FOR EXAMPLE.

YOUR BENEFITS: POWERFUL CUTTING, PRECISION AND HIGH AVAILABILITY AT LOW UNIT COSTS.

ALL THE DETAILS AT A GLANCE

POWERFUL PERFORMANCE, HIGH DYNAMICS – THE KEY FACTS OF THE 18 SERIES:

|

Travel X-Y-Z 830-550-630 mm Power, max. 37,00 kW Spindle distance DZ 320 mm or 400 mm Spindle speed, max. up to 16.000 min-1 Chip-to-chip time from from 1,90 s Axis acceleration, max. X-Y-Z 17-17-17 m/s2 Rapid feed, max. 75 m/min Number of tools, max. 60 or 2 x 35 Tool taper HSK-A63 / SK-40 Tool weight, max. 10,00 kg Tool diameter, max. 180 mm Tool length, max. 380 mm Automatic workpiece change from 3,50 s |