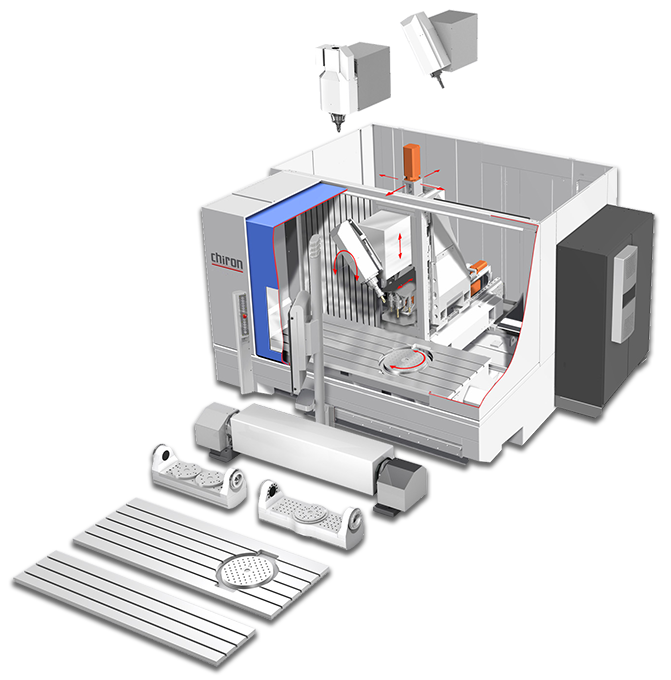

MILL Series CHIRON Machining Center

CHIRON

Powerful, dynamic and precise, as universal as your production tasks

Large, flexible working sites

High efficiency and high-power drives

Low product cost

Highest machining accuracy and quality

High stability

Quick setup

Easy to control

Easy to maintain

MILL series CHIRON machining center offers the best conditions for high-efficiency machining and its accurate results.

BENEFITS

Powerful, dynamic and precise, as universal as your production tasks

·- Large, flexible working sites

·- High efficiency and high-power drives

·- Low product cost

·- Highest machining accuracy and quality

·- High stability

·- Quick setup

·- Easy to control

·- Easy to maintain

MILL series CHIRON machining center offers the best conditions for high-efficiency machining and its accurate results. The machines are characterized by high efficiency in the numerically controlled milling and stroke longitudinal direction from X to 6000 mm.

Spacious working sites and high-power drives

Universal set of options enables to adapt individually to application in question. All models of the same series are also stable, reliable and offer freedom of maintenance.

Your benefits: large working sites, high efficiency of milling and high-power drives

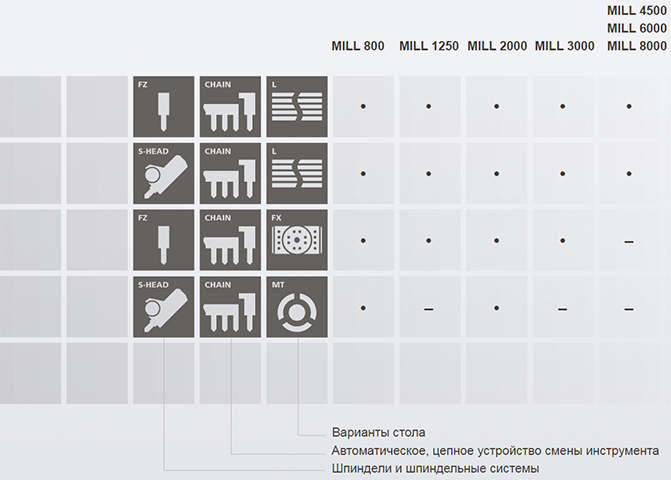

TECHNICAL DATA. BRIEF DESCRIPTION

High efficiency, large X-axis motion paths – key factors of MILL series:

|

X-Y-Z movement |

6000-915-715 mm |

|

Power, max. |

75 kW (40%ED) |

|

Spindle speed, max. |

up to 20000 rpm |

|

Torque, max. |

up to 280 Nm |

|

Chip-to-chip tool change time, from |

2.90 sec |

|

Rapid advance speed, max. |

75 m/min |

|

Milling rate in St 60, max. |

900 cm3/min |

|

Number of tools, max. |

163 |

|

Axial acceleration, max, X-Y-Z |

12-12-14 m/s2 |

|

Tool attachment taper |

HSK A-63 / SK 40 |

|

Tool weight, max. |

8.00 kg |

|

Tool diameter, max. |

160 mm |

|

Tool length, max. |

370 mm |