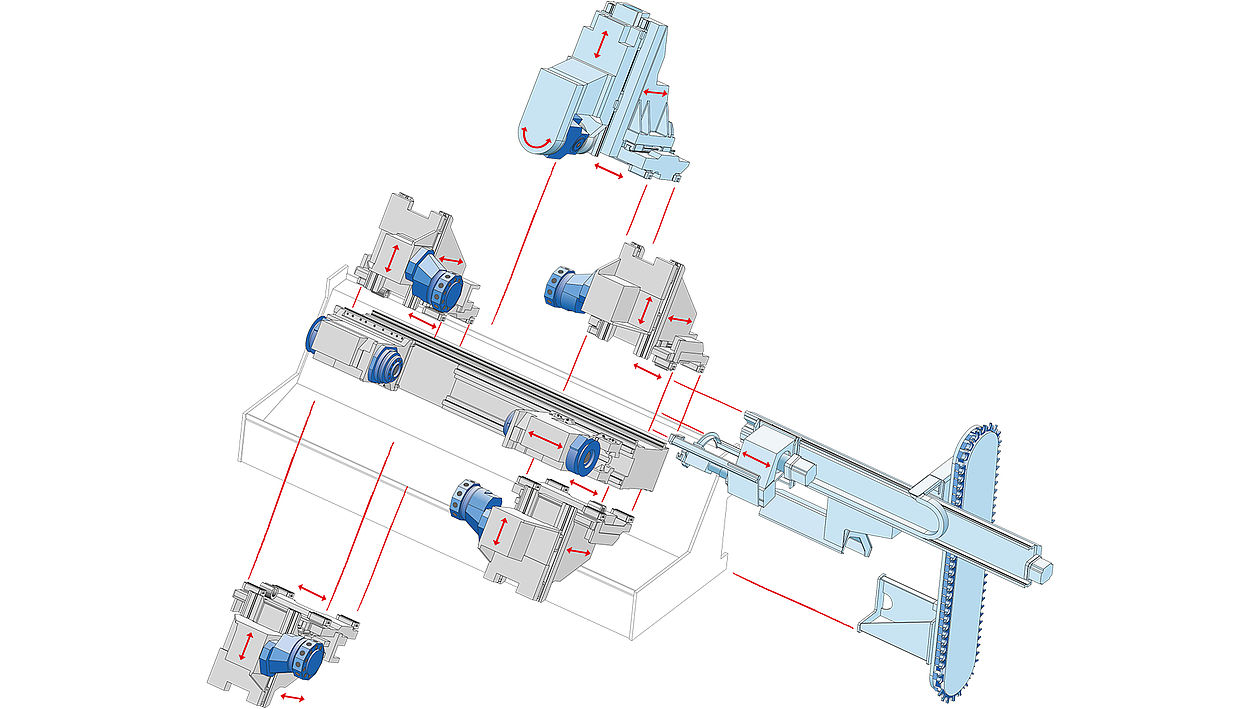

MODULAR SYSTEM

For optimal adaptation of the machine equipment to your specific tasks

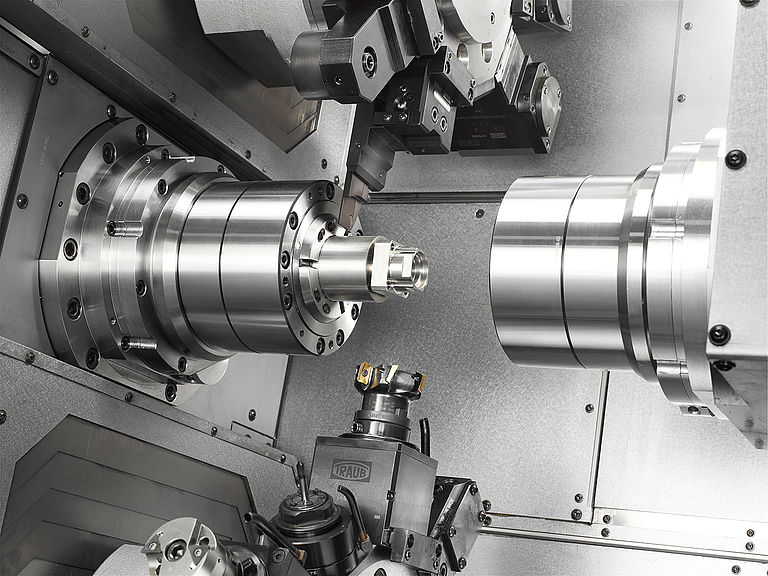

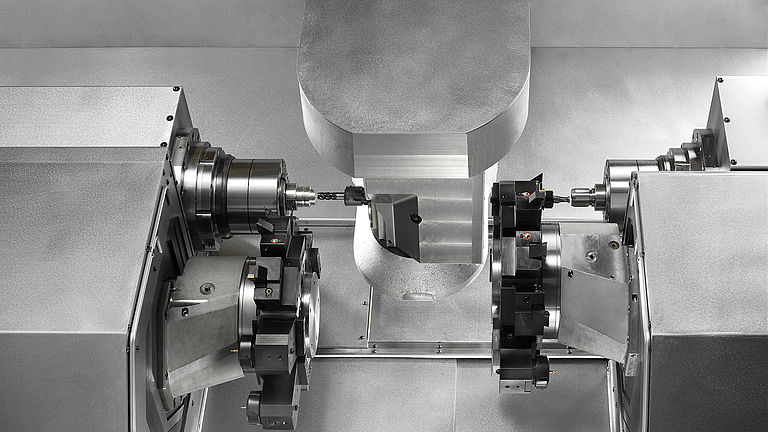

BASIC DESIGN

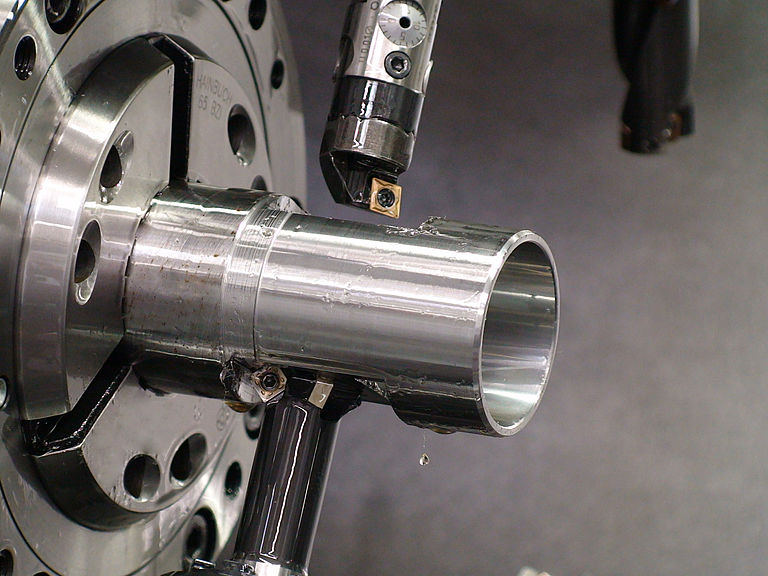

Compact machine frame made of iron casting with powerful ribs has high torsional and bending rigidity. It carries thermally symmetric headstock and linear carriage and sub-spindle guides. It provides excellent absorbing of vibration, exclusive dynamic rigidity and high thermal stability. Frame 60º inclination provides unobstructed chip falling.

MACHINE DIMENSIONS

·Bar diameter – up to 65 mm

·Chuck size – up to 175 mm

·Working length – up to 650 mm

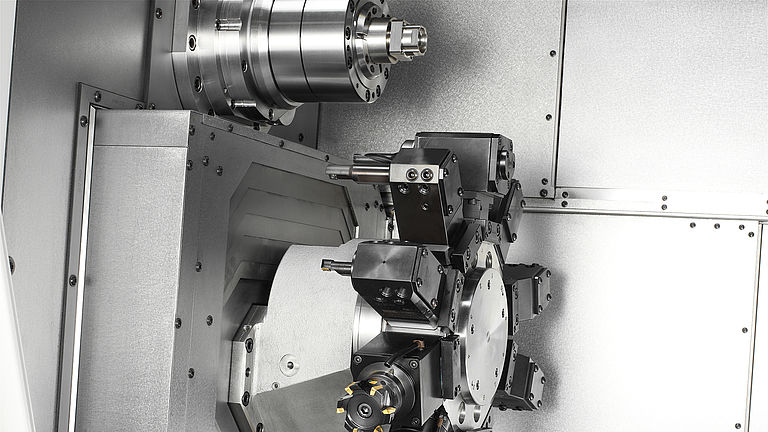

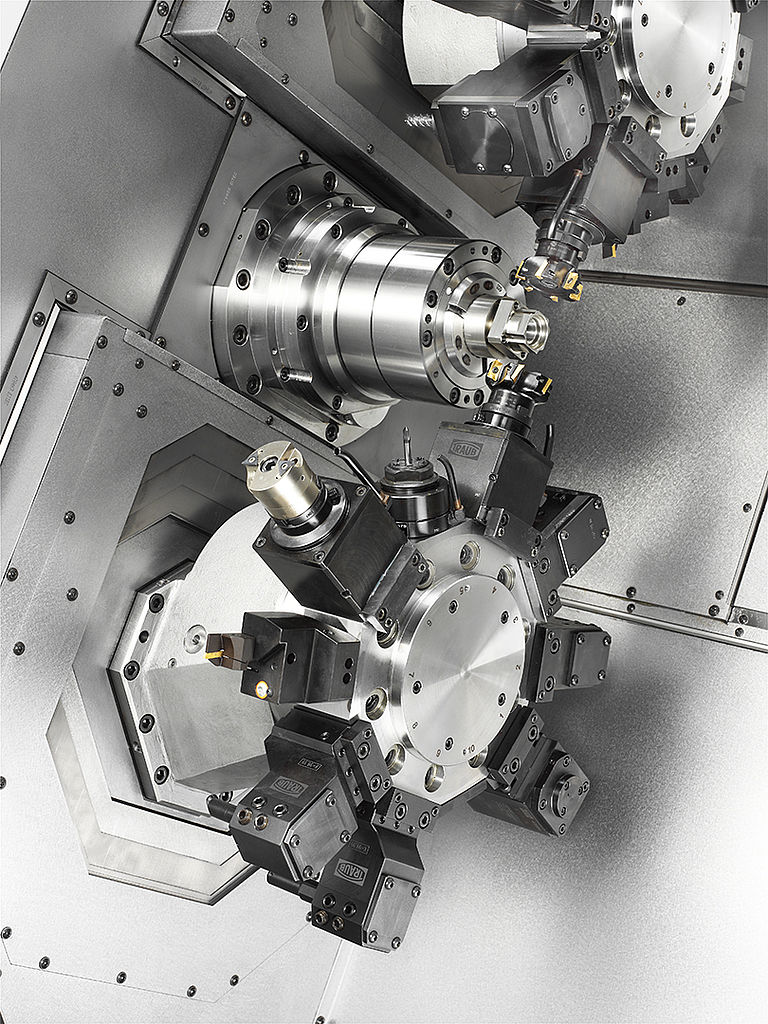

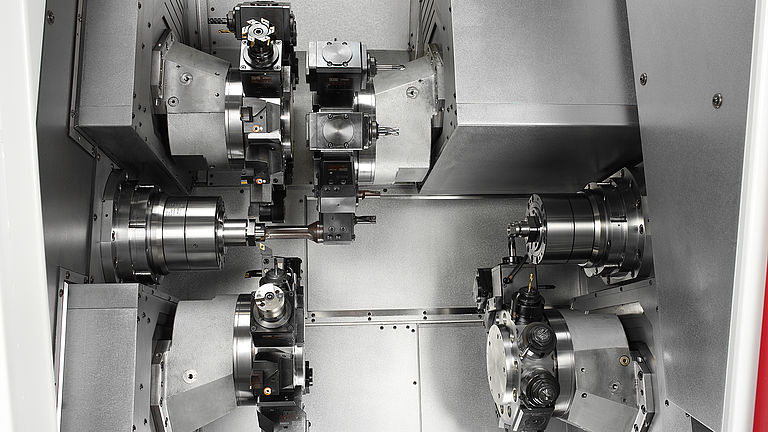

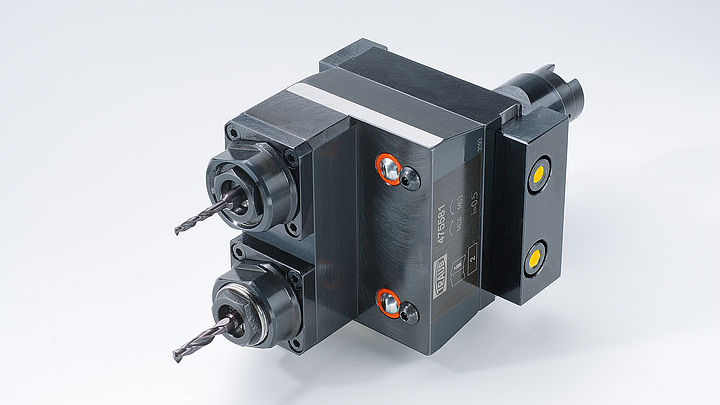

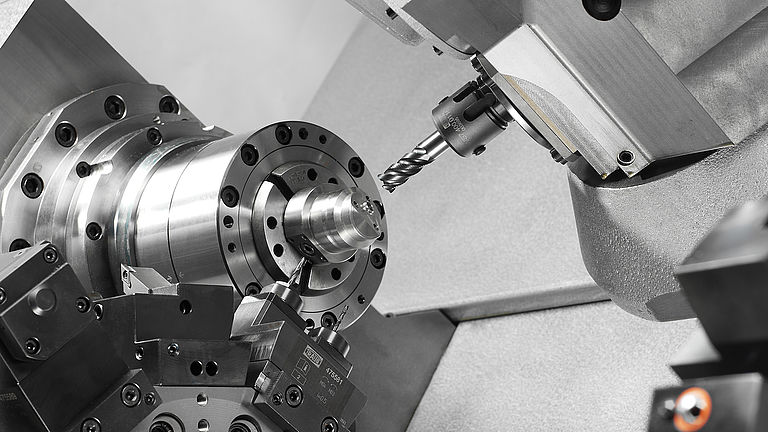

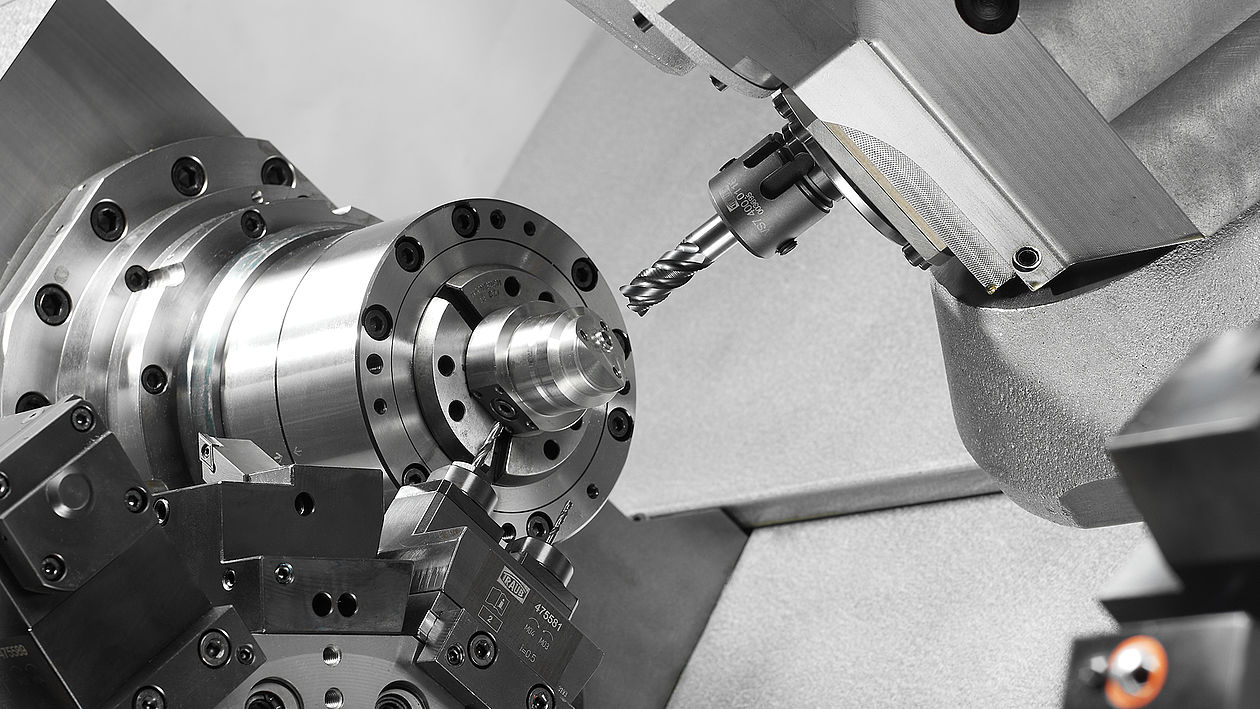

MAXIMUM EFFICIENCY USING TWO TURRETS

Tool holder for all turrets and all machining devices. Gears on both ends of our tool holders (TRAUB patent) enable to use cutting tool on the main spindle and sub-spindle. In conjunction with high-precision tool holder positioning it significantly reduces changeover time. Therefore, tool alignment is not required.

High speed, accuracy and reliability for maximum efficiency

CHIRON-WERKE GmbH & Co.KG – over 80 years of experience in the field of fine mechanics and mechanical engineering. Chiron specializes in the manufacture of vertical numerical control milling centers more than 30 years.

This experience in conjunction with the wealth of ideas, successful innovative solutions and dogged work of employees accelerates technological advance and provides Chiron with leading position in the world, including Russian, market in the field of manufacture of hi-tech metal-working equipment.

Enhanced Chiron product selection is the solution of virtually any problem. Thank to modular design, machining centers are manufactured both in base case and customized.

Chiron offers milling and milling-turning centers for manufacture of products and parts with high machining requirements with the axes from 3 to 13 and from 1 to 6 spindles for single-piece, batch and mass production. Traditionally leading fields of CHIRON technologies application:

- automotive industry;

- aerospace industry;

- fine mechanics;

- energy sector;

- turbine bucket manufacture;

- tool-making facilities;

- medicine;

- jewelry industry.

Company continuously improves technical parameters of the machining centers, develops new solutions, works up specific interests of a customer keeping pace with new trends and constantly growing requirements in the field of metal-working.

Chiron machining centers and turnkey solutions, whether the question is small batch production or large batch one, reduce the machining time by means of the following solutions:

- basket-type record quick tool change system. Tool change time: from 0.9 sec, that enables to save up to 800 working hours per annum;

- equipment of machine with swinging table providing nonstop product machining;

- application of robotics in the working process;

- process train design.