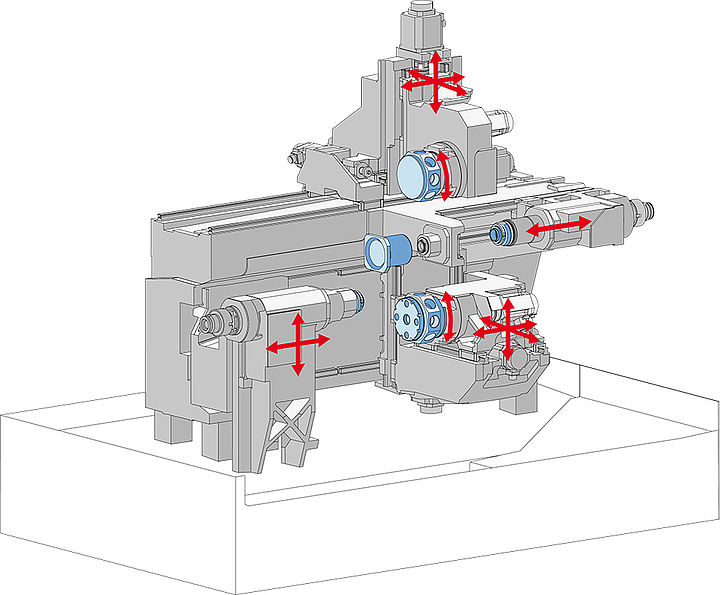

MACHINE CONCEPT

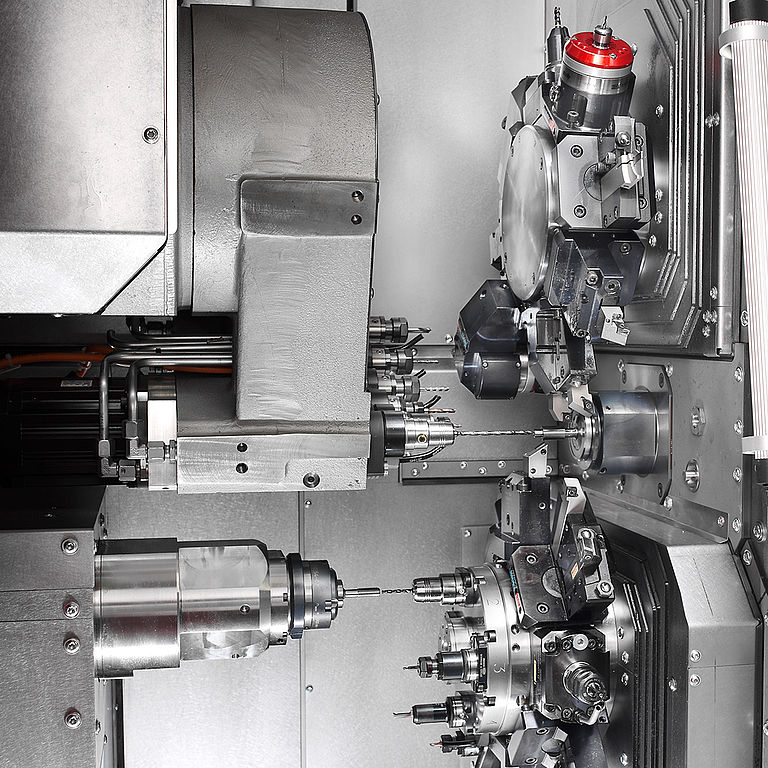

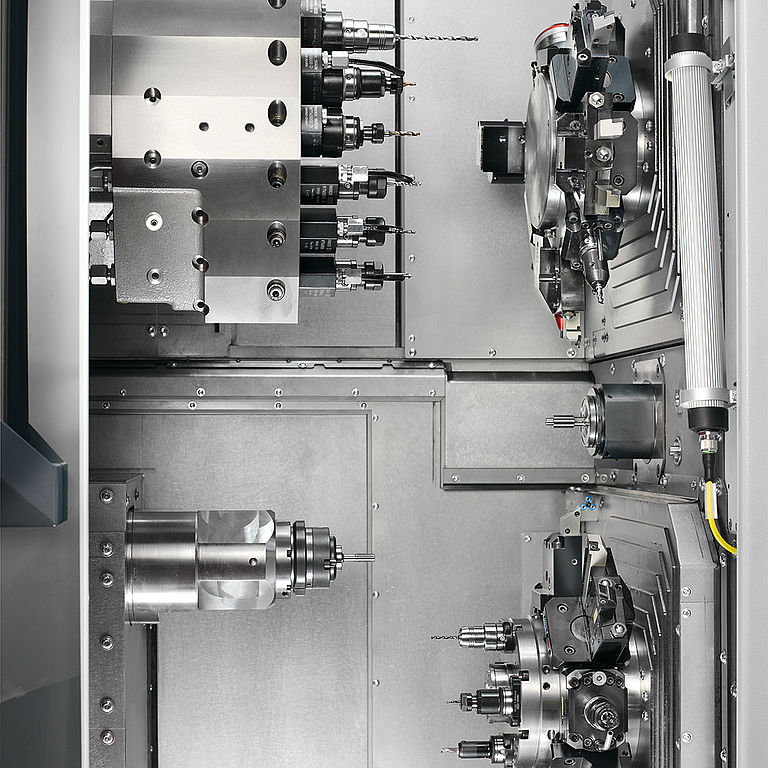

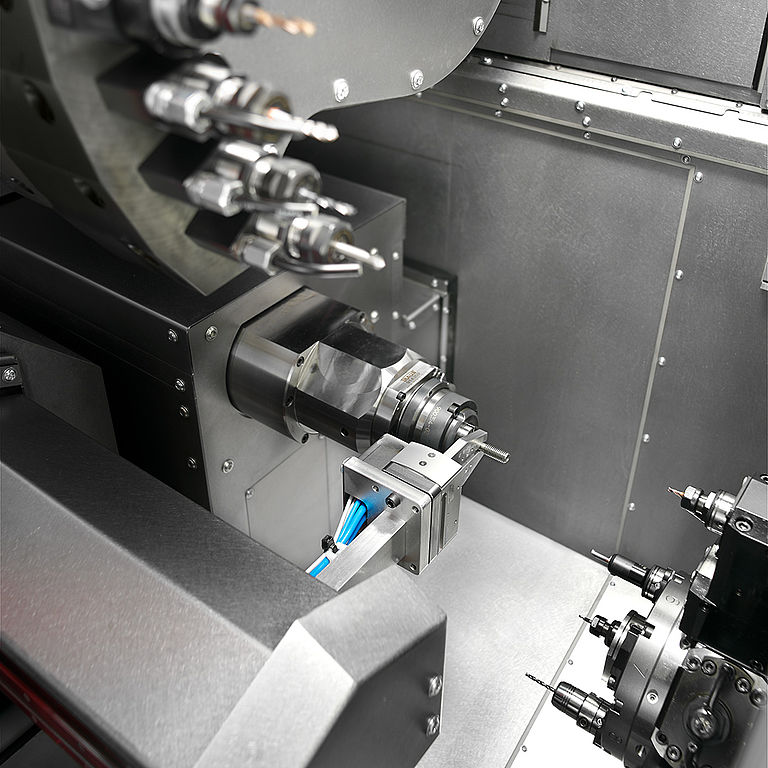

Machine TRAUB TNL20 concept is intentionally adjusted for user’s day-to-day requirements. In such a way, machine cinematics provides efficient machining using up to four tools at the same time. Wide and vertically designed working site contributes to required degree of freedom and high technological process reliability.

Key benefit of efficiency a machine obtains owing to its extremely high dynamics. New type of cast iron frame provides the basis for the best vibration absorbing properties. Moreover, high stiffness and thermal resistance provide optimal blank piece quality.

TNL20-9

Precision machining using up to three tools at the same time.

TNL20-11

With additional front apparatus – effective and more lean production using up to four tools at the same time

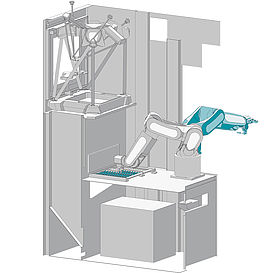

ROBOT MODULE IXCENTER

INTELLIGENT AUTOMATION – PLUS IN FLEXIBILITY AND EFFICIENCY

By means of robot module iXcenter it is possible to quickly, reliably and flexibly automate blank and/or part loading/unloading. Robot module is ergonomically build in machine. In the course of changeover, it is possible to move a module to the left that enables unimpaired access to machine working site.

In the production process a robot module is fixed in front of machine working site. Then, robot enters into working site through the automated machine door that automatically opens behind the robot module

BLANKS AND FINISHED PIECES

·Compact vertical magazine with working stock up to 14 pallets

·Pallet dimensions: 400x300 mm

·Minimum pallet height: 25.4 mm

·Pallets with blanks are loaded at the top, pallets with finished pieces are removed at the bottom – without production interruptions

·Supply and removal of pallets is made by robot

·Easy to program using Makro cycles

EXPLOIT MORE OPPORTUNITIES

Space over the vertical magazine can be easily used for subsequent processes, such as cleaning, measurement, deburring, etc.

Basic complete set provides preparation for integration of fully automated three-dimensional measuring element.

·It is possible to control Closed-Lop technological process