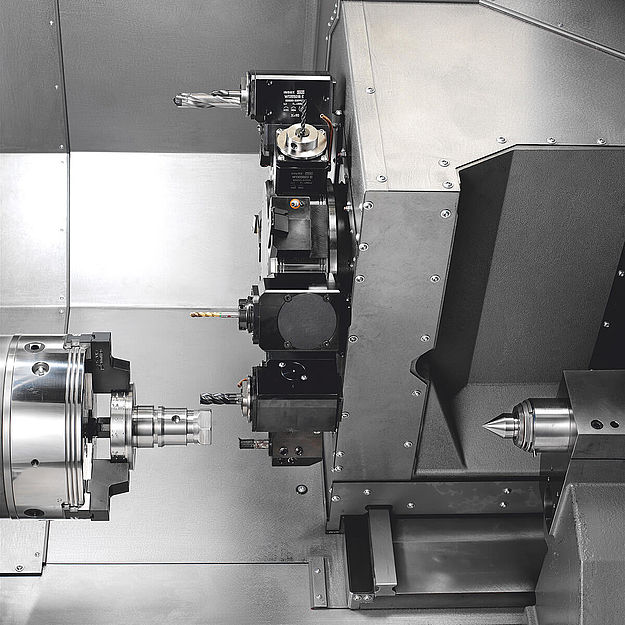

B400 IN FOCUS

STRUCTURED MACHINE DESIGN

INDEX B400 is the sequential modernization of time-proven production solutions. With individual fitting out this new flexible universal machine finds its place in tool making and prototypes, and both in medium- and large-batch production. Knowledge gathered throughout the few decades is reflected in numerous structural members, e.g. metal casing over the main spindle providing protection against interference when using long boring bars, and so on.

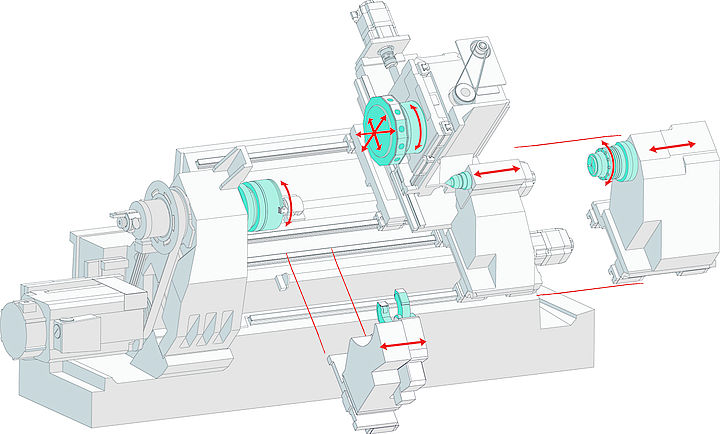

COMPONENTS

Main spindle

·Bar diameter – 82 mm, clamping chuck size – up to 315 mm

·Rotational speed – 4000 rpm

·Spindle horsepower – 24 kW (at 40% duty ratio)

·Torque – 550 Nm (at 40% duty ratio)

·Brake for index axis division

Turret with vertical axis on compound rest

·12 drive positions

·Fastener VDI30 according to DIN 69880 with patented W-gearing

·X 255 mm / Y ±60 mm / max. Z-direction working length up to 750 mm

·Machining capability up to 70 mm under center of rotation

·6000 rpm, 5.5 kW, 19.5 Nm (at 25% duty ratio)

Tape-controlled tailstock

·Electronic, freely positioned

·Large-sized linear bearings

·Clamping force up to 10 000 N with electronic control

·Centering cone MK5 or SK30

Steady rest (option)

·Electronic positioning capability

·Numerical control programmability

·Clamping range 12-152 mm

Part remover (option)

·Max. Æ = 82 mm

·Max. length = 200 mm

·Max. weight = 8 kg

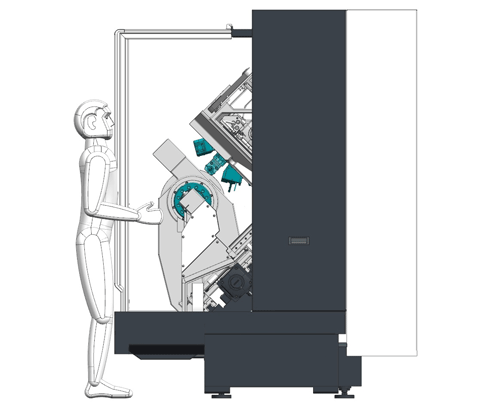

ERGONOMIC CONTROL CONCEPT

Spacious working site provides the best access when adjusting the machine INDEX B400. Main spindle and tool turret are best available and, accordingly, provide quick and soft setup and re-equipment. Well-thought-out working site concept with steeply inclined and flat floor provides perfect chip flow and prevents its accumulation.

·Quick setup

·Excellent working site access

·Good chip flow

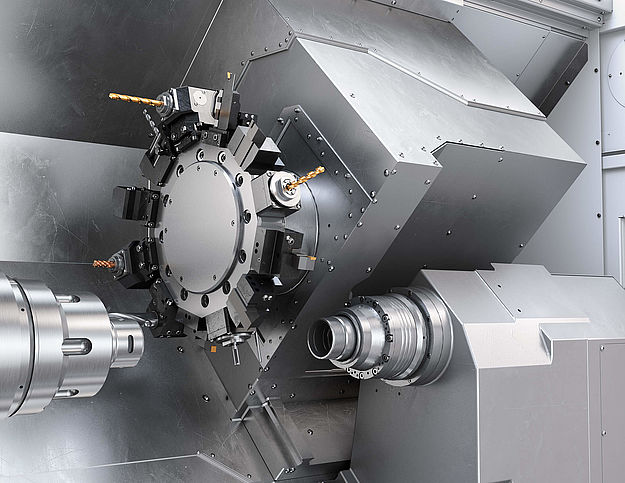

W-GROOVE PRINCIPLE

INDEX patented W-gearing for high stability of tool change repeatability.

·Quick setup and re-equipment

·High tool change accuracy owing to long fixation groove

·Cutting insert resistance extension

·Compatibility with DIN 69880

·Suitable for fixed tools and power-driven tools

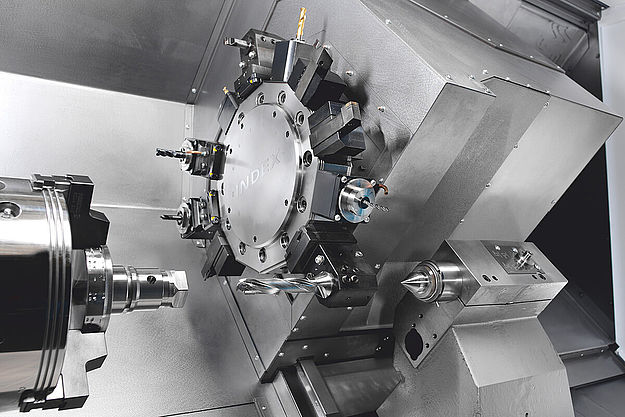

WIDE RANGE OF PARTS

UNIVERSAL LATHE B400 PROVIDES CAPABILITY FOR MACHINING OF GREAT VARIETY OF PARTS MADE OF BAR UP TO 82 MM IN DIAMETER AND IN THE CHUCK UP TO 315 MM