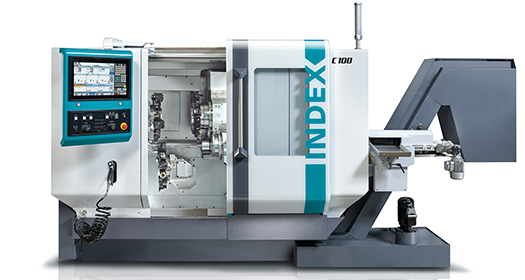

C100 IN FOCUS

C100 CONTROL SYSTEM

Focus on control and production – including Industry 4.0. iXpanel – control system for direct data exchange of rapid automatic lathe C100 with your business structure. iXpanel consists of the latest-generation Siemens S840D SL-based multi-touch 18.5" touch screen, as well as Industry 4.0 functionality. Integration of “Virtual Machine” is optional, e.g. for 3D modeling and changeover for the next blank machining in parallel with production.

iXpanel-i4.0 ready in more detail

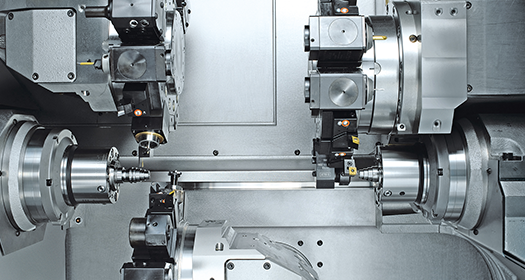

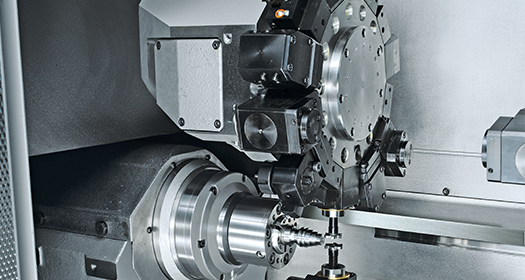

CINEMATICS

Machine frame vertical structure ensures optimum chip flow and good working site access. Two Y-axes on the main spindle or one Y-axis on the main spindle and one Y-axis on the sub-spindle are optional. Therefore, it is possible to separate even complex working processes and to cut a cycle time.

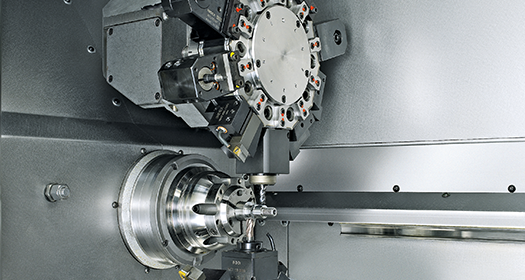

WORKING SITE

Machine INDEX C100 opens up fresh opportunities for rapid manufacture of bar turned parts. Despite its compact dimensions, INDEX C100 provides a wide working site for integrated part machining

ROBOT MODULE IXCENTER

INTELLIGENT AUTOMATION FOR EXTRA FLEXIBILITY AND EFFICIENCY

Thanks to optional robot module iXcenter it is possible fast, safe and flexible supply/removal of blanks and/or finished products.

Robot module is ergonomically coupled with machine. In the course of setup it can simply move to the right that provides unimpeded access to working site. In production mode, module iXcenter fixes in front of machine working site. Then, robot access to working site is provided through the machine sliding cap that opens automatically behind the robot module.

Simple blank and finished piece manipulation

·Compact vertical magazine with working storage up to 22 pallets

·Pallet dimensions: 600x400 mm

·Minimum pallet height: 25.4 mm

·Pallets with blanks are loaded at the top, pallets with finished pieces are removed at the bottom – at any time without production interruptions

·Installation and removal of pallets is made by robot

·Simple macros programming

Exploit more opportunities

Subsequent processes, such as cleaning, measurement, deburring, etc. can be integrated into robot module.

Ready for operation

·Six-axis robot for useful load of 7.5 kg with integrated gripper control

·Standard module specification includes double gripper

·Standard module specification includes 22 pallets (without inserts for various types of parts)

·Despite the separate unit, simple internal motion is possible